This is a project I’ve been experimenting with at Techshop Durham. It is a laser cut business card that folds up to create a working caliper. I’ll probably make some for myself, Rod-o-Rama, and lintqueen.

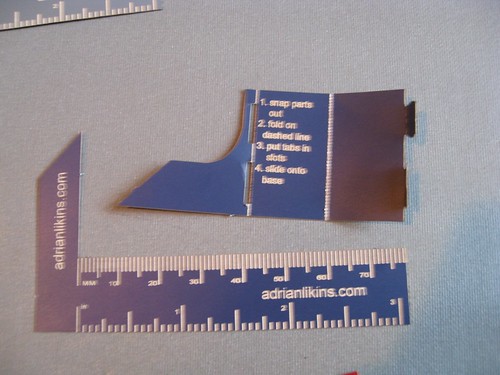

The card in “ready to hand out” mode

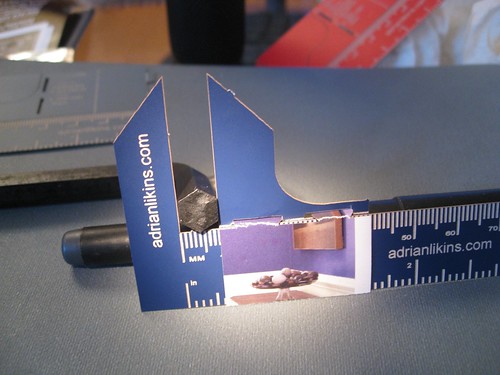

Card assembled, ready to use. These particular examples were actually cut out of paint chip cards (lintqueen’s idea).

In action, measuring an 8mm hex key. Accuracy and precision are not too bad for something folded out of paper.

It’s cut and engraved with the epilog laser cutter at Techshop Durham. Initial design scratched out on paper, transferred to Inkscape, final tweaking in Corel Draw (actualy, lots of tweaking, since it did a horrible job importing the svg).

It still needs some refinements, like better instructions and possibly an illustration or two. I have some minor aesthetic tweaks in mind as well, but this version is mostly complete.

The corel draw source file is here. That file could use some cleanup, and I’d like to get it back into a open format like svg, but that will do for now. Consider it under Creative Commons.

Business Card Caliper by Adrian Likins is licensed under a Creative Commons Attribution 3.0 United States License.

Based on a work at www.adrianlikins.com.